Roots vacuum pump for INPA-Screw vacuum pump-Vacuum pump manufacturer of vacuum negative pressure station

Mr Mao +86-13958606260

Roots vacuum pump for INPA-Screw vacuum pump-Vacuum pump manufacturer of vacuum negative pressure station

Mr Mao +86-13958606260

inPower single-stage rotary vane pumps have been widely used in low vacuum and high vacuum processes for a long time. inPower single-stage rotary vane pump has the characteristics of long service life, low oil mist, and cost-effective use.

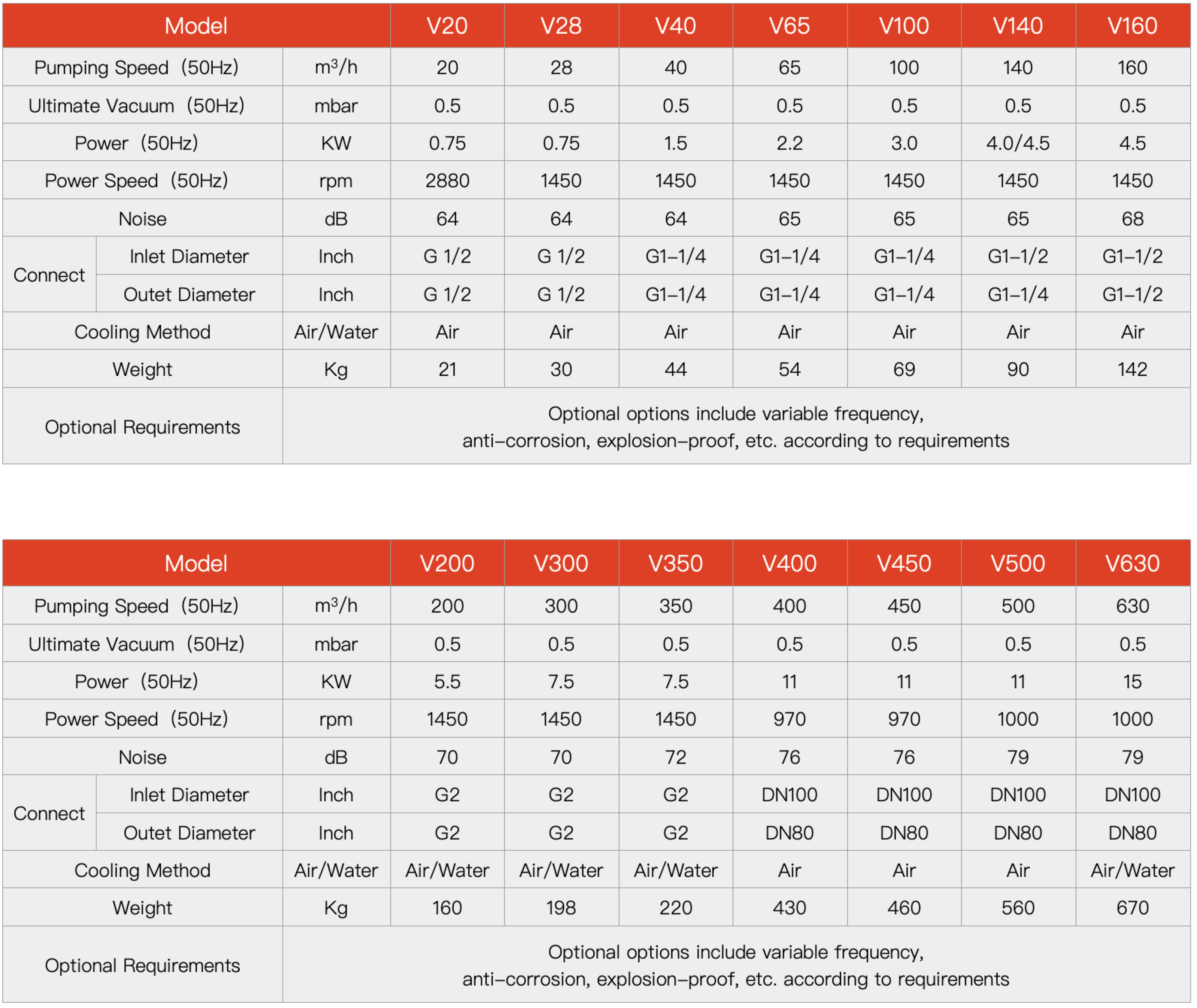

Model: V20/25/40/65/100/140/160/200/300/350/400/450/500/550/630

Ultimate pressure: better than 20Pa

Rated pumping speed 50 Hz: 20-630 m³/h

Rated pumping speed 60 Hz: 24-756 m³/h

Accessories and spare parts

1. Dust filter

2. Oil mist filter: a set of built-in

3. Vacuum pump oil: installed with the pump

4. Oil filter: installed with the pump

Specific environment and choice

Co-V version: When your use environment has mildly corrosive gases, such as acidic, alkaline and other environments, you can choose the Co-V version of the vacuum pump. By increasing the coating of the part of the pump body that contacts the pumped gas, the environment can be improved. The reliability of the lower pump body. (It is recommended to choose inPower-LGB series oil-free screw vacuum pump for strong corrosive environment)

H2O-V version: In oil filter, vacuum packaging, environmental protection, distillation and separation, etc. where there is more water vapor, the H2O-V version of the vacuum pump can be selected. Impal can increase the temperature of the pump by increasing the gas input, and use a specific vacuum pump. Measures such as oil can solve the condensation and retention of water vapor and improve the reliability of the vacuum pump.

HT-V version: In the fields of rubber vulcanization, vacuum smelting, vacuum heat treatment, vacuum brick making, etc., due to the high temperature of the pumped gas, the HT version vacuum pump can solve the vacuum application in this environment, and the allowable temperature is less than 200ºC.

EP-V version: explosion-proof, used in flammable and explosive environments, and can be equipped with explosion-proof vacuum pump accessories and body to meet the vacuum requirements in explosion-proof environments.

Application field

• Analysis (mass spectrometry, electron microscopy)

• Coating technology (surface protection, decorative layer, display, screen)

• Vacuum metallurgy (vacuum brazing, vacuum sintering, vacuum alloying, furnace manufacturing)

• Leak detection technology (vacuum equipment, car fuel tanks, airbag boxes, packaging)

• Lighting industry (lamp manufacturing)

• Drying industry (vacuum drying, transformer drying)