Roots vacuum pump for INPA-Screw vacuum pump-Vacuum pump manufacturer of vacuum negative pressure station

Mr Mao +86-13958606260

Roots vacuum pump for INPA-Screw vacuum pump-Vacuum pump manufacturer of vacuum negative pressure station

Mr Mao +86-13958606260

GXR Series dry screw vacuum system

One of the few high-vacuum dry screw vacuum units in the world

Innovative screw technology with automatic control function

InPower's new GXR dry pump improves vacuum performance to a new level. With the unique screw technology and the world's leading high-efficiency driver, advanced temperature control and long maintenance intervals can be realized, greatly reducing your maintenance costs.

Advanced shaft seal technology

inPower GXR is extremely innovative technology to protect the gearbox from contamination and keep the vacuum space free of oil. Non-contact long-life seals ensure efficient sealing and provide you with reliable vacuum performance.

Smart pump provides consistent worry-free output

The intelligent onboard control panel enables you to automatically control the production process through automatic start/stop routines, power saving, green frequency conversion mode, and self-cleaning options.

Advanced pumping mechanism design

inPower GXR is a silent power. The updated technology and design can ensure low vibration and quiet operation, which is very suitable for your clean working environment. The reinforced screw rotor can be gradually compressed to improve thermal control at each stage of the process and optimize the vacuum.

Can provide customized solutions for your application

The GXR series can be customized to provide the best performance in various applications. From light to medium applications, we can help you design and apply one or more groups to form a complete vacuum system to meet your precise requirements.

Long-life bearings and lubrication

You can expect to use oil-lubricated gears to extend the service life and save maintenance costs, eliminating the need for grease and maintenance intervals.

Widely used in many fields:

• Lithium battery: effectively solve the problems of strong corrosiveness and electrolyte

crystallization in this industry

• Semiconductor

• Chemical, pharmaceutical: product distillation, drying, degassing, material transport-

ation, etc.

• Vacuum coating: evaporation plating, sputtering plating, ion plating, etc.

• Drying: drying of fruits, vegetables, wood, etc.

Single or multiple vacuum solutions

Oil-free screw compressor station: According to different pumping speed requirements, the ultimate vacuum is 1Pa

Within, screw pumps with different pumping speeds are connected in parallel to meet the requirements of large pumping speeds.

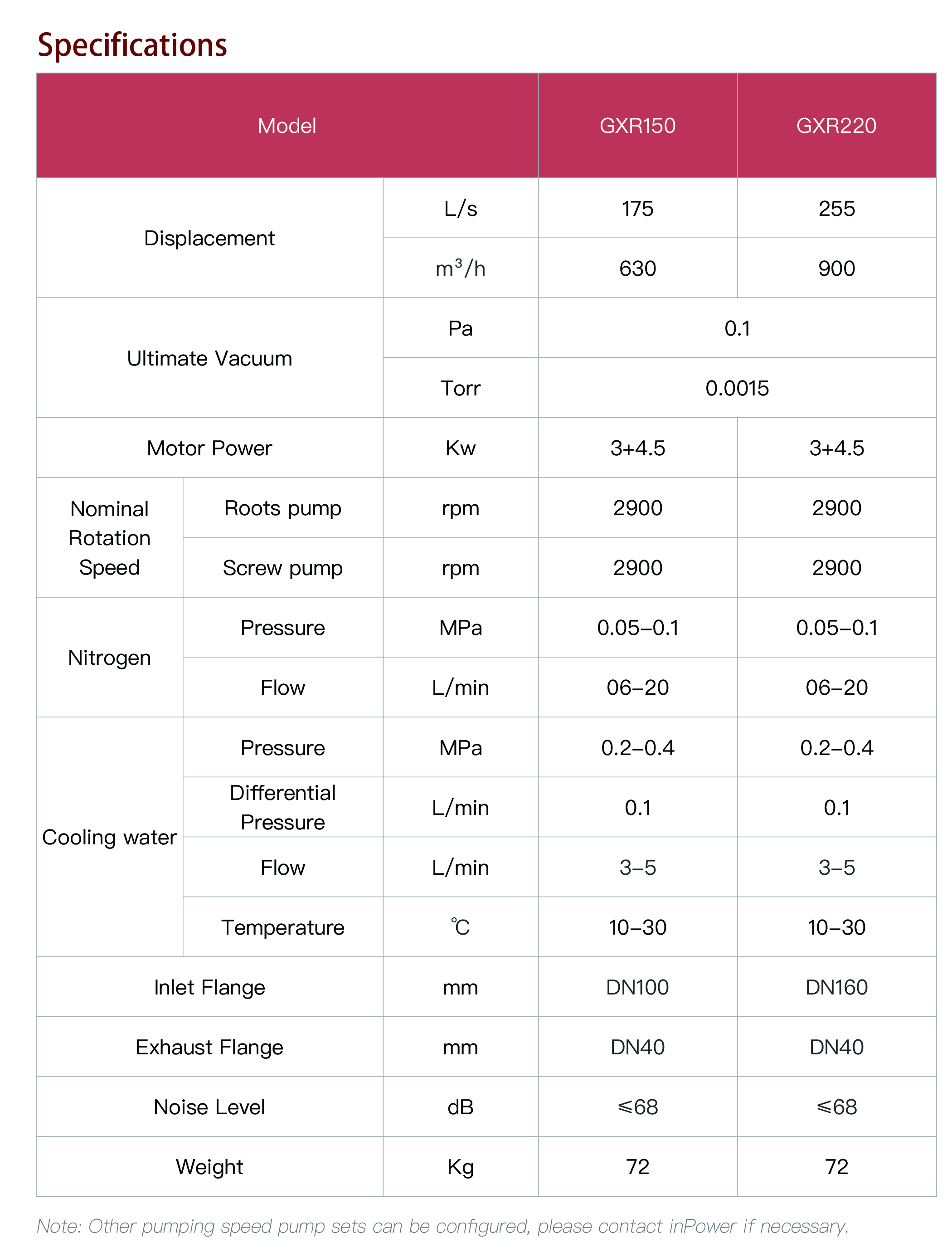

Oil-free screw/Roots machine station: When your ultimate vacuum requires 0.1Pa or more

At high temperatures, high ultimate vacuum can be achieved through oil-free screw and Roots (single-stage or multi-stage)

With large pumping speed requirements.

More complex station requirements: when the working environment contains high corrosiveness, high dust,

When working conditions such as high water vapor, flammable and explosive, etc., you can contact the Impulse Vacuum Technical Team

Docking and formulating customized vacuum system solutions in specific environments.